GPR1.1 12kV Dry Air Insulated Ring Main Unit (Environmentally friendly)

The GPR1.1 series dry air insulated ring main unit switchgear is a new generation of small, intelligent, and environmentally friendly ring main unit switchgear with international level, developed according to the needs of the construction and renovation of the distribution network in the new era. Its technology draws on the technical advantages of SF6 fully insulated ring main unit at home and abroad. Through electromagnetic field simulation analysis, dry air is used as the insulation medium, combined with vacuum arc extinguishing technology, completely replacing SF6 gas and retaining the technical advantages of SF6 fully insulated ring main unit. Realizing zero emissions of SF6 is a new generation of green and environmentally friendly products.

- Overview

- Recommended Products

The GPR1.1 series dry air insulated ring main unit switchgear is a new generation of small, intelligent, and environmentally friendly ring main unit switchgear with international level, developed according to the needs of the construction and renovation of the distribution network in the new era. Its technology draws on the technical advantages of SF6 fully insulated ring main unit at home and abroad. Through electromagnetic field simulation analysis, dry air is used as the insulation medium, combined with vacuum arc extinguishing technology, completely replacing SF6 gas and retaining the technical advantages of SF6 fully insulated ring main unit. Realizing zero emissions of SF6 is a new generation of green and environmentally friendly products.

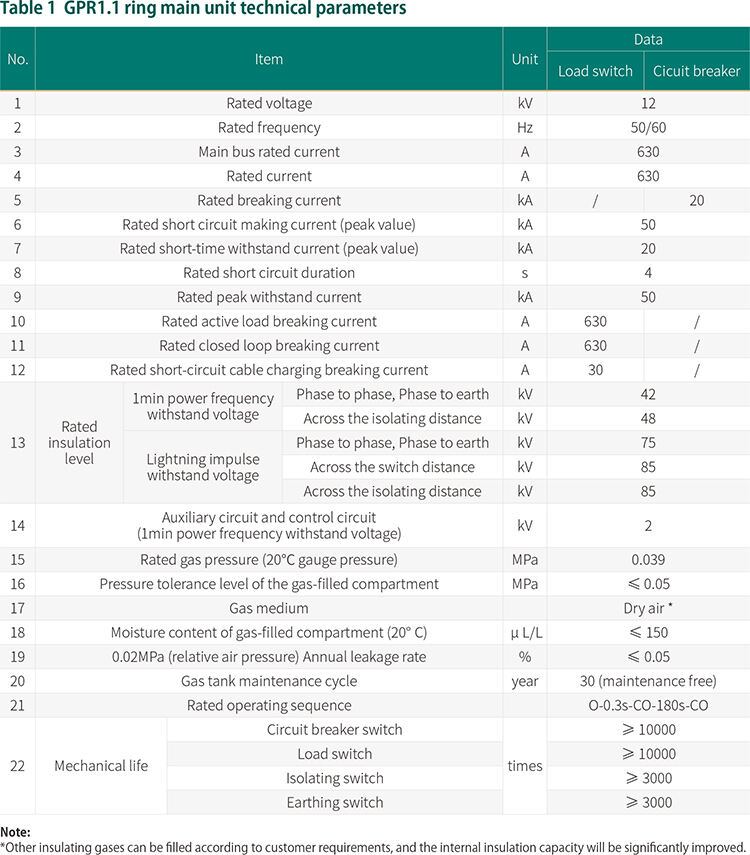

| Rated voltage | 12kV |

| Rated frequency | 50/60Hz |

| Rated current | 630A |

| Rated gas pressure (20℃ gauge pressure) | 0.039MPa |

| Pressure tolerance level of the gas-filled compartment | ≤0.05MPa |

| Gas medium | Dry air* |

| Moisture content of gas-filled compartment (20℃) | ≤150μL/L |

| Annual leakage rate (relative air pressure 0.02MPa) | ≤0.05% |

| Gas tank maintenance cycle | 30 years (maintenance free) |

| Compliance | Meets international safety standards such as ISO, IEEE |

Non polluting: Using specially treated dry air as insulation medium, green and environmentally friendly.

Miniaturization: Compact and compact, occupying less than a quarter of the traditional product area, saving land.

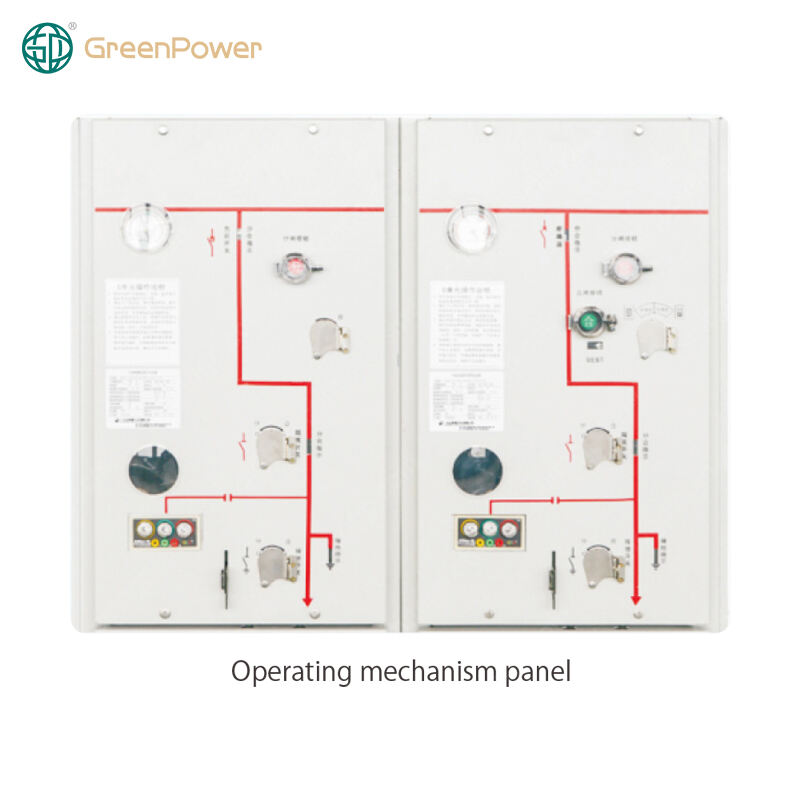

Visualization: There is a visual window corresponding to the three-station isolation and earthing switch, which can visually observe the isolation break and earthing status, improving the safety of use.

Zero gauge pressure: The internal dry air pressure is consistent with atmospheric pressure, and there is no gas pressure on the gas tank, greatly reducing the risk of air leakage.

High performance: The internal electromagnetic field balancing technology is used to evenly distribute the electric field inside the gas tank, achieving stable operation and ensuring electrical performance in dry air.

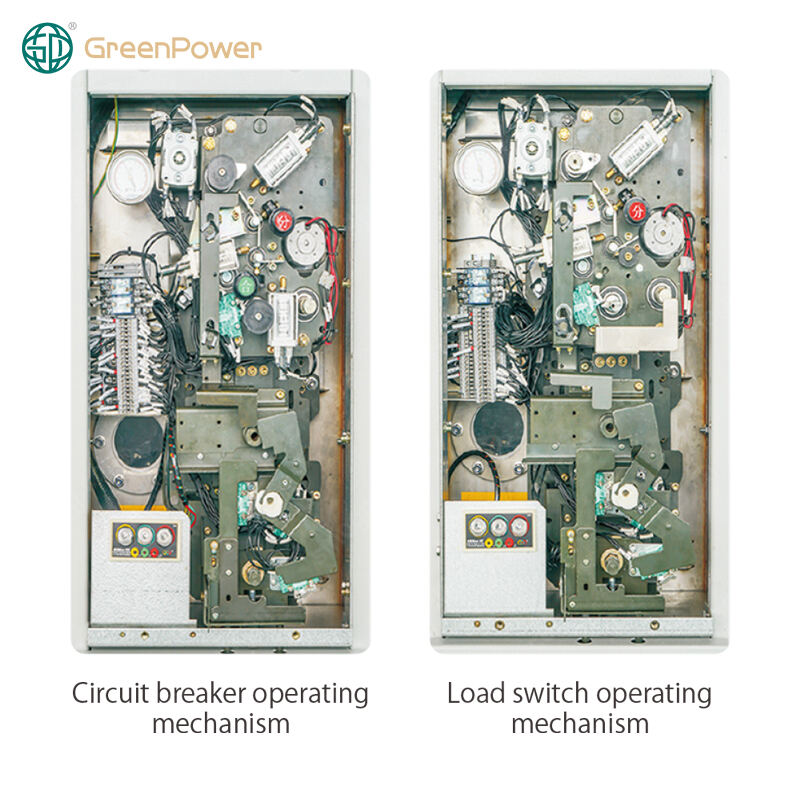

Safety: Adopting mechanical interlocking device with "five prevention" locking function; Install a pressure relief device at the bottom of the gas tank to protect the safety of operators in front of the cabinet.

Maintenance-free: The interior of the switchgear is filled with dry air, and the gas pressure is at atmospheric pressure. The components inside the gas tank are maintenance free for 30 years, greatly reducing the cost of comprehensive investment and having significant economic benefits.

Altitude: Less than 3000m

Ambient temperature: Maximum +40℃, Minimum -25℃; The daily average temperature does not exceed+35℃

Relative humidity: The average daily relative humidity does not exceed 95% and the average monthly relative humidity does not exceed 90%

Earthquake intensity: Not exceeding 8 degree

Use in environments that can withstand dust, moisture, and short-term immersion in water.

Note: When the actual use environment conditions are inconsistent with the above conditions, please consult with our company.

GreenPower provides professional smart switchgear solutions. Contact us immediately for free consultation and quotation. Our professional team will provide you with full service and technical support throughout the process.

Email: [email protected]

Tel: +86-18989782765

Fax: 057785500968