In today’s electrical systems like compact switchgear, power distribution cabinets, and equipment for renewable energy, space optimization is an especially important priority. Flexible busbars are being used in place of rigid busbars for compact designs due to their structural and performance advantages. Because rigid busbars are fixed in shape and hard to bend, they are used where space is not tight. Flexible busbars can be folded, bent, or twisted in almost any way to fit into tight spaces, while excellent electrical conductivity and mechanical strength are retained. GPSwitchgear, an electrical equipment manufacturer, fully incorporates flexible busbars into their compact switchgear and distribution solutions, thus improving product miniaturization and reliability. Here are the reasons why flexible busbars are used for compact designs.

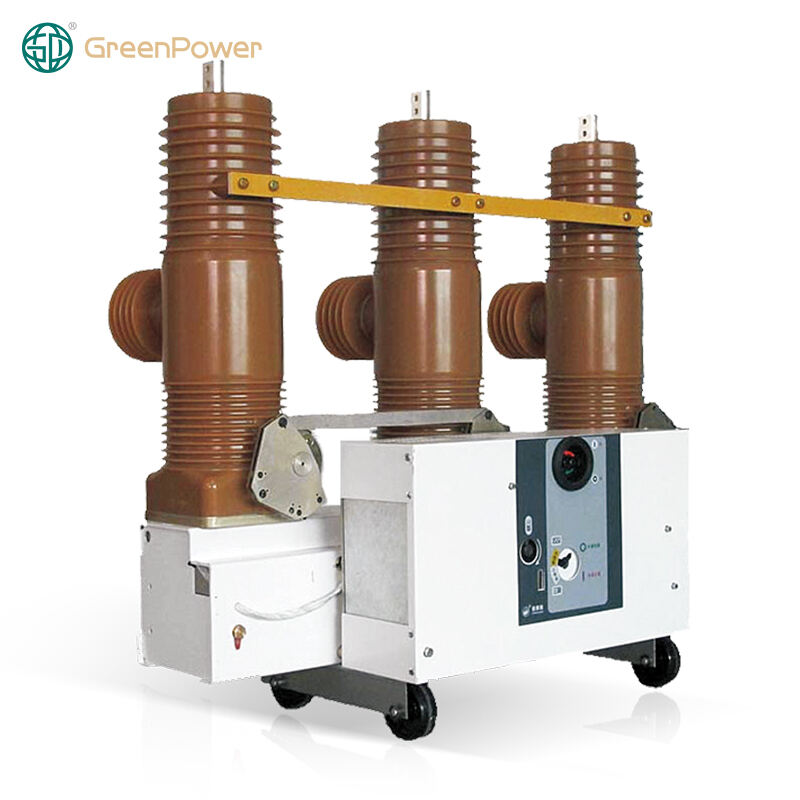

Busbar Flexibles have extraordinary flexibility which is their greatest advantage in designs to be compact. Busbar Flexibles can be constructed to be large rolls of thin copper or aluminum foil insulated with PVC or Silicone which allows copper to be manipulative. Busbar Flexibles can be twisted and turned to follow the internal framework of compact equipment which is impossible to achieve with rigid busbars made with solid copper. In compact switchgear busbar Flexibles can replace the need of large reserved space meant for rigid busbar installation which is made with solid copper. For instance in a medium voltage compact ring main unit which is less than 2 cubic meters in volume meant rigid busbar connections to the vacuum circuit breaker and the earthing switch in a vertical or horizontal larger space. Busbar Flexibles have high quality insulating flexible materials which retain their flexibility even for long periods of time and repeated usage to ensure busbar Flexibles are at their best performance and have long usage in space.

Rigid traditional busbar systems can eat up a lot of space because they have many connectors like bolts, brackets, and insulators to change direction or join components. Each of these connectors adds space to the system. Flexible busbars reduce the number of connectors needed, because they easily and directly link components that are at different angles or separated without needing an intermediate adapter. For example, joining a 10kV VCB (Vacuum Circuit Breaker) to a busbar in a small cabinet, a busbar would require 2 brackets and a right-angle connector that would take up 10–15 cm of space. Flexible busbars can be bent to connect the two points and save 50–70% space. Flexible busbars are also thinner (2-5 mm thick, 10-50 mm wide) compared to rigid busbars (10-20mm thick) which makes them easier to install in tighter spaces. This allows them to be installed in space between the cabinet's back panel and components. Thin flexible busbars can be used in compact designs to take advantage of the space that is available in a compact design.

To ensure busbar flexibility design cross-sections balance conductivity and space usage, GPSwitchgear makes sure that sufficient current capacity is accommodated while maintaining a slim form factor for ease of installation.

As high-density electrical systems get more closely packed the risk of poor current distribution and electromagnetic interference increases. Improperly designed systems tend to generate uneven and potentially harmful electromagnetic interference. Designs that employ flexibles busbars with multi-stranded or multi-foil configurations promote even current distribution. This occurs because each strand or foil independently ‘Counters’ the ‘Skin Effect' (the tendency of alternating current to concentrate on the surface of the conductor) and proximity effects. This means that flexible busbars can carry thousands of amps without overheating even when there is limited space (such as in compact electrical equipment). For instance, in a compact solar inverter (which is used in rooftop solar systems) flexible busbars not only connect the internal modules of the inverter but also facilitate the delivery of high currents generated by the solar panels to the inverter modules while sufficiently cooling the inverter-- a task poor heat dissipating rigid busbars struggle with. Moreover, the insulating layer of the flexibles busbars enhanced thermal performance with heat resistant materials such as silicone (which with stands temperatures as high as 180℃). This is particularly beneficial in compact designs. At GPSwitchgear, flexibles busbars are subjected to stringent current-carrying and temperature-rise testing to ensure that they can meet the high current demands of compact systems without compromising safety.

Mobile power stations, electric vehicle charging piles, and even industrial robots are examples of compact electrical systems that experience operational vibrations. As for rigid busbars, the fixed connections are susceptible to becoming loose or fracturing from continuous vibrations, which can lead to severe electrical issues. However, the flexible “shock absorber” structure of busbar flexible mitigates vibration absorption and stress at the connections. Moreover, the busbar flexible’s multi-strand design enables lateral movement fatigue avoidance, and the flexible insulating layer absorbs vibration energy. An example would be an emergency mobile compact substation where busbar flexible connects and withstands vibration internal components during movement or wind transportation. An anti-rigid vibration busbar would need an additional bracket, more space, and loose connection checks more often. GPSwitchgear’s busbar flexible is vibration tested (meeting IEC standards for industrial vibration levels) to ensure reliability in compact equipment, which is critical for the overall balance in equipment compact design. This is in dynamic conditions, which exposes the equipment to industrial vibration levels.

Limited access to compact electrical system components makes installation and upkeep challenging. The Busbar Flexible series alleviates this problem with its light, easy to handle flexible busbars for compact and modular systems. Flexible busbars offer a significant weight advantage, up to 50% for the same current carrying capacity, making this series a preference in compact spaces. Unlike rigid busbars, which installation requires exact lengths, cuts, and alignment drillings (time-consuming in compact cabinets), flexible busbars can be trimmed to length on-site and bent to fit, cutting installation time 40-60%. For Maintenance, when a part in a compact system needs swapping, busbar flexible can be reconfigured without disassembling adjacent parts, saving time and reducing the chances of collateral damage. For instance, in a compact medium voltage switchgear cabinet, to replace a faulty relay connected via busbar flexible, one only needs to disconnect the two ends of the busbar. Replacing a relay connected via rigid busbar requires a laborious process of removing adjacent brackets and connectors. For busbar flexible, GPSwitchgear supplies installation documents with bending and connection radius recommendations to further ease on-site compact design work.

Hot News

Hot News2026-02-02

2026-01-23

2026-01-20

2026-01-18

2026-01-16

2026-01-15