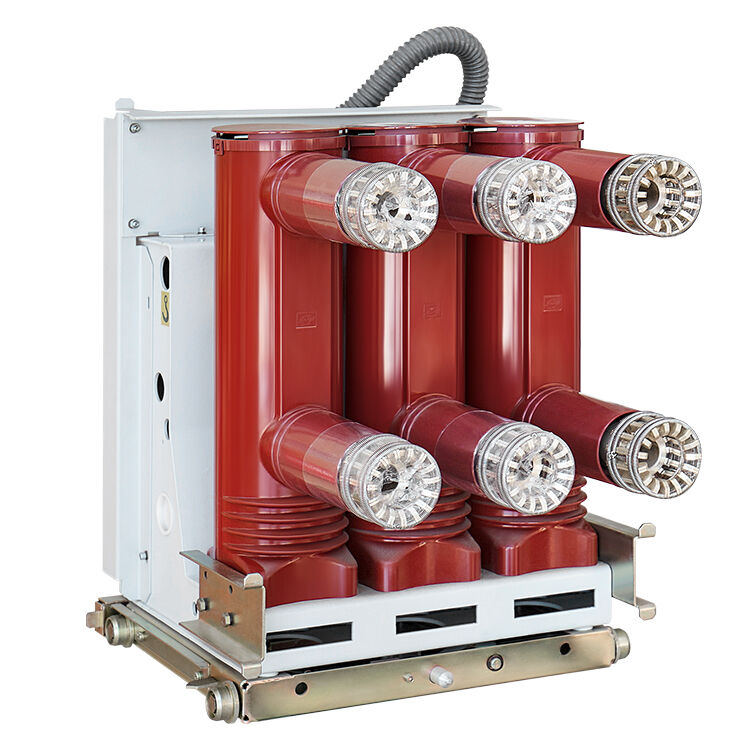

A withdrawable vacuum circuit breaker (VCB) comes equipped with a rail guided chassis that glides right out of energized switchgear even when the busbars are still live. The whole setup is built around modularity so techs can swap out bad units in less than half an hour without cutting off power upstream. For places where every second counts like data centers and hospitals, this matters a lot since studies show downtime there costs over seven hundred forty thousand dollars each hour according to Ponemon Institute research from 2023. When operators need to work on these breakers, they just unlock them first, pull them out to what's called the test position, unplug those secondary controls, then take the whole thing out completely while keeping everything else running normally in the background.

The vacuum interrupter technology works inside completely sealed chambers, which makes these devices resistant to problems like oxidation, getting wet from moisture, and other atmospheric contaminants that typically cause failures in those old SF6 and oil filled breakers we used before. Because of this protection, the contacts don't degrade as much over time, so maintenance folks can actually space out their checks from once a year to every three years instead. Some major power companies have shared stories about cutting down on inspections by almost two thirds since they switched to vacuum circuit breakers. That translates into saving around 200 man hours each year at individual substations while still meeting all the necessary reliability requirements set forth by IEEE C37.09 and IEC 62271-100 standards.

Three independent, purely mechanical interlocks eliminate reliance on procedural controls or operator judgment:

After switching to withdrawable vacuum circuit breakers, a Tier III data center substation saw its Mean Time To Repair drop by nearly 80%. What used to take technicians 4.2 hours now takes just under an hour for each replacement. This massive time savings comes from cutting out steps like turning off entire panels, taking apart complicated components, checking arc flash boundaries, and coordinating multiple teams at once. Over the course of 16 maintenance cycles per year, this adds up to 52 hours saved overall and prevents around $350k in lost operations costs when we factor in that downtime costs roughly $15k per hour. The bottom line? Labor costs dropped by almost half per maintenance cycle too. And let's not forget about those pesky installation errors - plug and play setups cut down on rework problems significantly since studies show incorrect installations cause about 23% of all electrical maintenance delays according to Electrical Safety Review last year. Plus, none of these gains came at the expense of safety standards; everything still meets NFPA 70E requirements.

| Operational Impact | Before | After | Reduction |

|---|---|---|---|

| Mean Time To Repair (MTTR) | 4.2 hr | 0.9 hr | 79% |

| Technician Hours per Event | 10 | 4.3 | 57% |

| Annual Downtime Costs | $672k | $144k | $528k |

The problem with high voltage maintenance has always been knowing for sure if equipment is properly isolated. Visual break indicators tackle this exact issue head on. Traditional lockout tagout systems rely heavily on following procedures correctly, keeping accurate records, and people actually reading those tags properly. But these mechanical flags give workers something they can see right away when contacts separate inside the vacuum interrupter chamber. When the breaker moves to disconnect position, there's this bright red marker that lines up perfectly with inspection windows from several different viewing points around the equipment. This gives clear proof that everything is safely isolated regardless of what circuits are involved. Looking at data from arc flash incidents in 2023 shows something pretty impressive too. These visual indicators cut down on mistakes made during re energization by about 89 percent. That means technicians can get into work areas much quicker while still being confident no power remains in the system.

VCBs that can be withdrawn offer real long term value because they last longer, are easier to maintain, and don't require dealing with dangerous gases. When looking at Total Cost of Ownership or TCO, which covers things like regular maintenance, unexpected fixes, labor costs, spare parts, and meeting environmental standards, there's about a 37% cut in what companies spend on maintenance over ten years compared to those fixed mount SF6 breakers. Why does this happen? Mainly because vacuum interrupters need checking only 60% as often as others do. Plus, there's no need to handle SF6 gas anymore, so all that leak testing goes away along with the paperwork required by regulations. These savings stack up pretty nicely for plant operators concerned about both their bottom line and safety concerns.

| Component | Withdrawable VCB | Fixed-Mount SF6 Breaker |

|---|---|---|

| Annual Maintenance Cost | $600 | $950 |

| Total 10-Year Maintenance | $6,000 | $9,500 |

| Relative Savings | 37% lower | Baseline |

Tool-free access, minimal part wear, and energy-efficient operation further reinforce lifecycle savings—freeing capital for strategic infrastructure upgrades rather than reactive maintenance.

Hot News

Hot News2026-02-02

2026-01-23

2026-01-20

2026-01-18

2026-01-16

2026-01-15