Жогорку деңгээлдеги электр коопсуздугу стандарттарына ылайыктык колдонуучунун коопсуздугун жана өнүмдүн эффективдүүлүгүн көрсөтөт. GPSwitchgear маркалуу электр жабдыктарынын производствосу моторду башкаруу борборлору неге стандарттарга ылайык болушу керек экенин түшүндүрөт: «Бул стандарттар системалардын изоляциясына, жерге туташтырууга жана кыскартылган чынжырдан коргоого баса атат», — дейт GPSwitchgearдин командасы. «Моторду башкаруу борборлорунда диэлектрик беркинчтик сыноолорун өткөргөн чыкма жана контакттор болушу керек», — дейт GPSwitchgear. Коопсуздук стандартдарын эсепке албасак, башкаруу борборлорун жана жабдыктарын жоготуп алабыз, ошондой эле абдан зарыл эмес электр өрттөрүнө себепчи болобуз. GPSwitchgear бизди убартат: «Талаптарга ылайык боло алыштын жалгыз жолу – материалдарды тандоодон баштап акыркы жыйналышкагы чейинки өндүрүштүн ар бир кадамына коопсуздукту киргизүү».

Туура жабдыкты колдонуу дагы ошончолук маанилүү. «Моторду башкаруу борборундагы булутту программалануучу логикалык контроллерлер сыяктуу түрдө туура эмес жеткилүүчүдөн алынса, — деп түшүндүрөт GPSwitchgear, — бул башка компоненттердин иштен чыгышына алып келет».

Мисалы, моторду башкаруу борборлорун өндүрүүдө өнөр жай деңгээлиндеги PLC колдонуу системаны экстремалдуу өнөр жай шарттарында (мисалы, экстремалдуу температура же тозок) узак мөөнөттүк иштөөгө мүмкүндүк берет. Төмөнкү сапаттагы стандарттарга ылайык келген компоненттер иштен чыгуунун жогорку жыштыгына шарт түзөт, анткени бул компоненттердин түзүлүшүнөн улам колдонуучулар үчүн техникалык кызмат көрсөтүү чыгымдары көбөйөт. Кагыйдалардын эрежеси катары, ишке жарамдуулук жана уюмдуулук үчүн компоненттерди сынама текшерүү моторду башкаруу борборун өндүрүүдө катаал кадам болуп саналат.

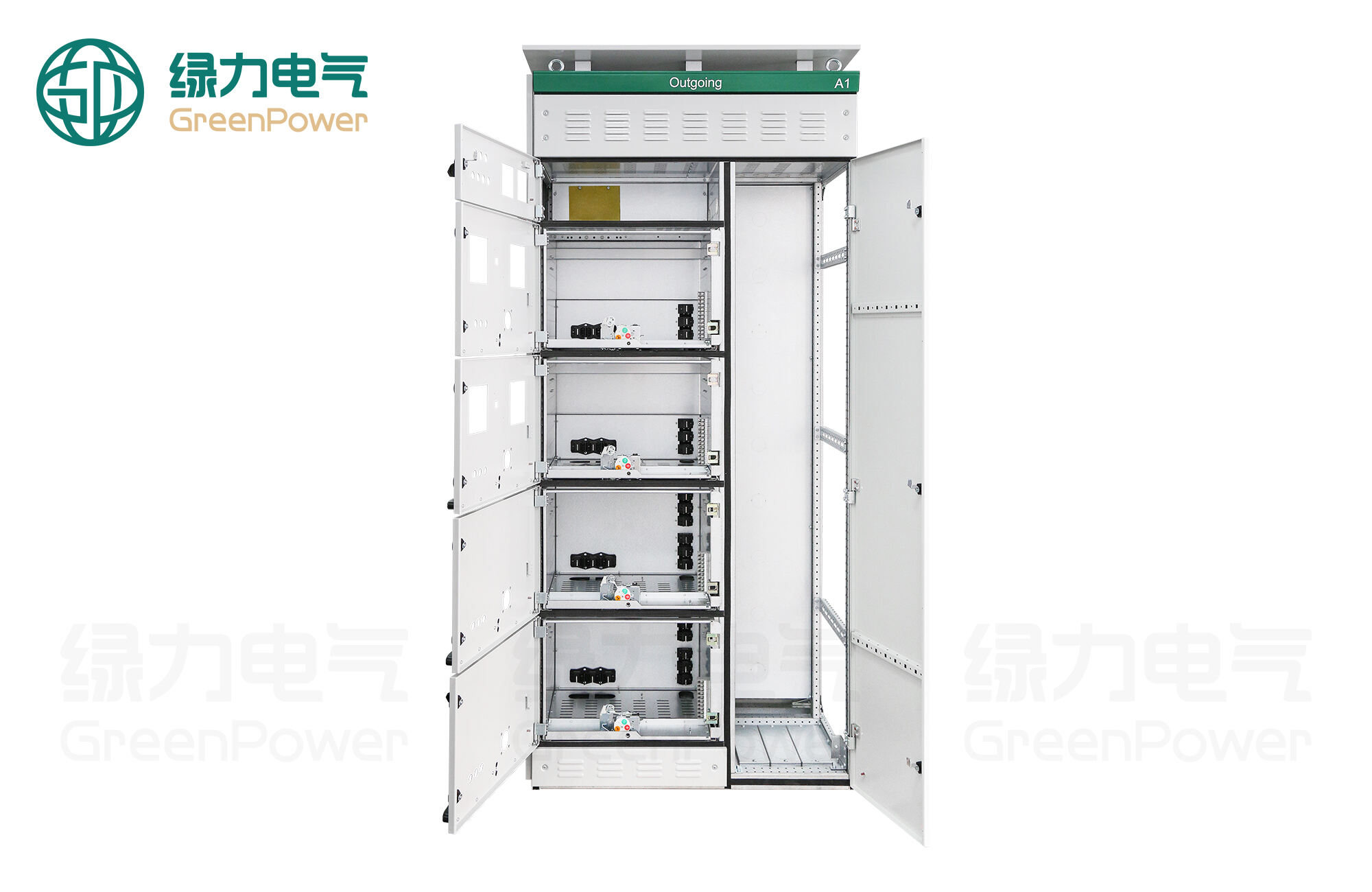

Моторду башкаруу борборунун өндүрүшүндө так тактап коюу – бул системанын туруктуулугуна, техникалык кызмат көрсөтүүгө жана иштөө тургундугуна таасирин тийгизгендиктен, дагы бир басымдуу чогуу. GPSwitchgear моторду башкаруу борборун өндүрүштө туура техника – туура өлчөмдөги сымдарды колдонуп, терминалга каршы саат жебесине карай крутящий момент берип коюу, ошондой эле компоненттерди жылуулук чачыраткычтар менен техникалык кызмат көрсөтүүгө ылайык орнотуу деп белгилейт. Мисалы, моторду башкаруу борборун өндүрүш фазасында документтер менен сымдардын чыныгы уникалдуу бутактуу системасын колдонуп, арбакча сымдардын тартипсиздигин жок кылуу үчүн сымдарды башкаруу системаларын коюу маанилүү. Бул арбакча сымдар системасындагы ийгиликсиздикти жокко чыгарып гана койбой, техниктердин тез арада тартипсиздикти жоюуга чара көрсөтүшүнө да жол ачат. Моторду башкаруу борборунун өз алдынча баалуулугу анын өндүрүшүндө технологияны колдонууга терең байланыштуу, мисалы, автоматташтырылган торцовый ключтар сыяктуу ыкма, ал терминалды мыкты бекемдөө аркылуу туташуу маселелерин камсыз кылат. GPSwitchgear бир нече өндүрүш сызыктарында моторду башкаруу борборлорун кыйынчылык менен тактап коюу соңку өнүмдүн бирдейлигин жакшыртууга мүмкүндүк берет деп ишенет.

Акыркысы, жылуулукту эффективдүү чачыратуу — мотордун башкаруу борборун өндүрүш үчүн эсепке алынышы керек тагы бир фактор. Белгиленгендей, мотордун башкаруу бордоро өздөрү иштөө жүрүшүндө көп мөөнөткө чейин компоненттерди бузуп же толугу менен иштебей калуусуна алып келүүчү жылуулук бөлүшөт.

GPSwitchgear боюнча, моторду башкаруу борборлорун өндүрүшкөн сайын кароо керек болгон элементтердин бири - системанын энергия тыгыздыгы жана ал ашыкча жылуулукту таратуу чараларын (мисалы, желдеткич менен жабдылган корпус, өстүк шайман же радиатор) кандай белгилейт. Мисалы, оор өнөр жай секторунда моторду башкаруу борборлорун өндүрүш үчүн жогорку кубаттуу моторду башкаруу борборлорун колдонуу керек болсо, системадагы ауа айланышын камсыз кылып, температураны 40℃ төмөн кармоо үчүн эки шайман колдонуу зарыл. Эгерде жылуулук тарбетилсе, борбор күтүүсүз өчүп калышы мүмкүн жана компоненттердин иштөө мөөнөтү 30-50% га чейин кыскарышы мүмкүн. Ошондой эле GPSwitchgear моторду башкаруу борборлорун өндүрүш үчүн жылуулуктык симуляциялык тесттердин натыйжасында пайда болгон «ысык чектер» оптимизацияланышы керек деп, мындай учурлар үчүн суутуу системасы алдан ара саналышы керек экенин билдирет.

Өндүрүш процессинин талаптарын канааттандырууда ийкемдүүлүк мотор контролдүү борборун өндүрүүдөгү негизги жагдай болуп саналат. Чындыгында, GPSwitchgear тарабынан өндүрүш, казылып алуу, суу иштетүү сыяктуу көптөгөн өнөр жайлар үчүн баса белгиленип отурган мотор контролдүү борборду өндүрүүнүн элементтеринин бири дагы болуп саналат. Талапка жараша мотор контролдүү борборлордогу корпусдор борбордун перифериясына ылайык келтирүүгө болот жана мындай учурда өндүрүш процесси казылып алуу компаниялары үчүн кеңири колдонулган эксплозияга каршы системаларды минималдуу кылууга багытталат.

GPSwitchgear компаниясындагы моторду башкаруу борборунун өндүрүш сызыгы ыңгайлуу тапшырымдарды өткөрүп чыгууга жумшалган. Инженерлер долбоорлордун өзгөрүшү боюнча клиенттер менен байланышта болушат, модулдуу жыйналыш кошумча спецификалык элементтерди тез киргизүүгө мүмкүндүк берет. Нишалык өнөр жайлар үчүн моторду башкаруу борборун өндүрүү кызматтары ыңгайлаштыруу мүмкүнчүлүгүнсүз ийгиликсиз болот. GPSwitchgear башкача иштөө ыкчамдыгы менен стандартташтыруу ыкчамдыгын баланста кармоо ар кандай өнөр жайлар үчүн бир нече клиентти камсыздоо үчүн маанилүү экенин эстен чыгарбайт.

Ысык жаңылыктар

Ысык жаңылыктар2026-02-02

2026-01-23

2026-01-20

2026-01-18

2026-01-16

2026-01-15