Electric motors are valuable to the operational efficiency of manufacturing plants, water treatment facilities, and even mining operations. For the maintenance of safety and equipment longevity, effective motor management becomes paramount. MCC Switchboards (motor control center switchboards) specialize in the central control, protection, and automation of multiple motors. This control element solves the issues of control points being too distant from each other, faults being too frequent, and loss of inefficient energy. MCC Switchboards are not general-purpose switchboards and must be used in industrial motor management. As a professional electrical equipment manufacturer, GPSwitchgear refines the design of MCC switchboards to fit a range of motor management from small workshops to large industrial facilities. In this post, we will look at how the MCC Switchboard enhances motor management in a number of ways.

Management of motors has been and is still done in a decentralized manner. Each motor has a local controller. This leads to multiple operation points, complicated wiring, and high management costs. The MCC switchboard solves this problem by centralizing control. Depending on the model, 10 to 50 motors can be controlled in a single cabinet, or cabinet bank. Each motor has a dedicated control module in the MCC switchboard, and operators can control the motor’s start, stop and speed adjustment through one Human-Machine Interface (HMI) or local push buttons. In a food processing plant, for instance, operators can control 20 conveyor belt motors and switch all the motors from one control room, rather than walking to 20 local control panels. This centralization definitely reduces operational time, and effort and simplifies wiring. The MCC switchboard reduces cable use by 40 to 60 percent, and this decreases installation costs and wiring errors. The MCC switchboard also enables operators to control motors through remote industrial communication protocols, and access management from a SCADA system. This adds to operational control.

Overload, short circuits, phase loss, and under voltage are faults that can occur on motors, and unattended, can lead to motor damages, operational losses, and even safety risks. To assist motor management, the MCC switchboard integrates full motor protection functions within each motor control module. These modules incorporate the following protection functions: 1) Overload protection: thermal overload relays or electronic protectors assess currents and trip the motor when excessive current flow is detected and maintained for a pre-determined period which is set to avoid damaging the motor windings. 2) Short circuit protection: motor and circuit wiring damage is prevented by quickly interrupting circuits using circuit breakers or fuses that are embedded in the motor control modules. 3) Phase loss protection: the power supply can be monitored and a motor stopped when one phase is lost which will prevent overheating in a matter of minutes during single phase operation. 4) Under voltage/ over voltage protection will protect the motor insulation and mechanical parts by shutting the motor or giving an alarm during excessive supply voltage and is triggered by low voltage.

Consider a pump for a water treatment plant. If a pump's motor connected to an MCC switchboard loses a phase, the switchboard quickly stops the motor and issues an alert. This prevents costly repairs and stops the plant's water supply from running dry. The MCC switchboard from GPSwitchgear uses protection components with response times within 0.01 seconds for reliable fault detection and protection.

To efficiently manage motors, visibility of their operating status in real time is crucial to avert potential problems that can develop into serious faults. Recognizing this, the MCC switchboard integrates monitoring sensors along with data collection capabilities. Every motor control module in the MCC switchboard has sensors that monitor critical indicators such as motor current and voltage, temperature, power, speed, and operating time. This information reached the MCC switchboard’s main controller, which is displayed on the HMI, and is kept in the local data base for future reference. This data can be used in assessing motor performance, for example, an increase in motor current may suggest bearing wear, while an increase in temperature of the winding may diagnose insulation deterioration. This feature of real time monitoring facilitates predictive maintenance. Repair/ replacement of motor components can be done much closer to the actual need as opposed to schedule maintenance which may be too early or too late for the actual conditions, reducing costs to maintain the motor and extending the service life of the motor. The MCC switchboard is also able to analyze data and forecast trends.

Every industry has energy operational costs. For every industry, they must contain energy consumption costs, with industrial motors consuming anywhere from 60-70% of electricity. The MCC switchboard plays a huge role on the management of motors by optimizing the energy efficiency in multitude of different ways. For starters, MCC switchboards have integrated variable frequency drives (VFDs) into the motor control modules. VFDs allow one to control the speed on the motor during every phase of load demand. Instead of having the motor run on full speed, VFDs allow the motor to run slower during low demand periods. For instance, in a factory, a fan motor may only required to run 70% speed during low demand periods. The motor's energy consumption during the low demand periods can be saved by 30-50% with the use of a VFD when compared to a fixed speed operation. Additionally, the MCC switchboard can monitor motors’ power factor, and unnecessary power factor correction (PFC) modules can be integrated: if the the power factor is too low due to the motor winding reactive power, energy loss in the supply system can be compensated. Lastly, the MCC switchboard has data monitoring to identify motors that are wasting energy. For instance, a motor that has abnormally high power consumption and is inefficient may need replacement or repair.

Using the MCC Switchboard can save a facility 10-20% on total electricity costs and provide seamless cost-efficient motor management. The MCC Switchboard by GPSwitchgear also provides detailed energy consumption and savings reports to enable facility managers to track and optimize energy use even further.

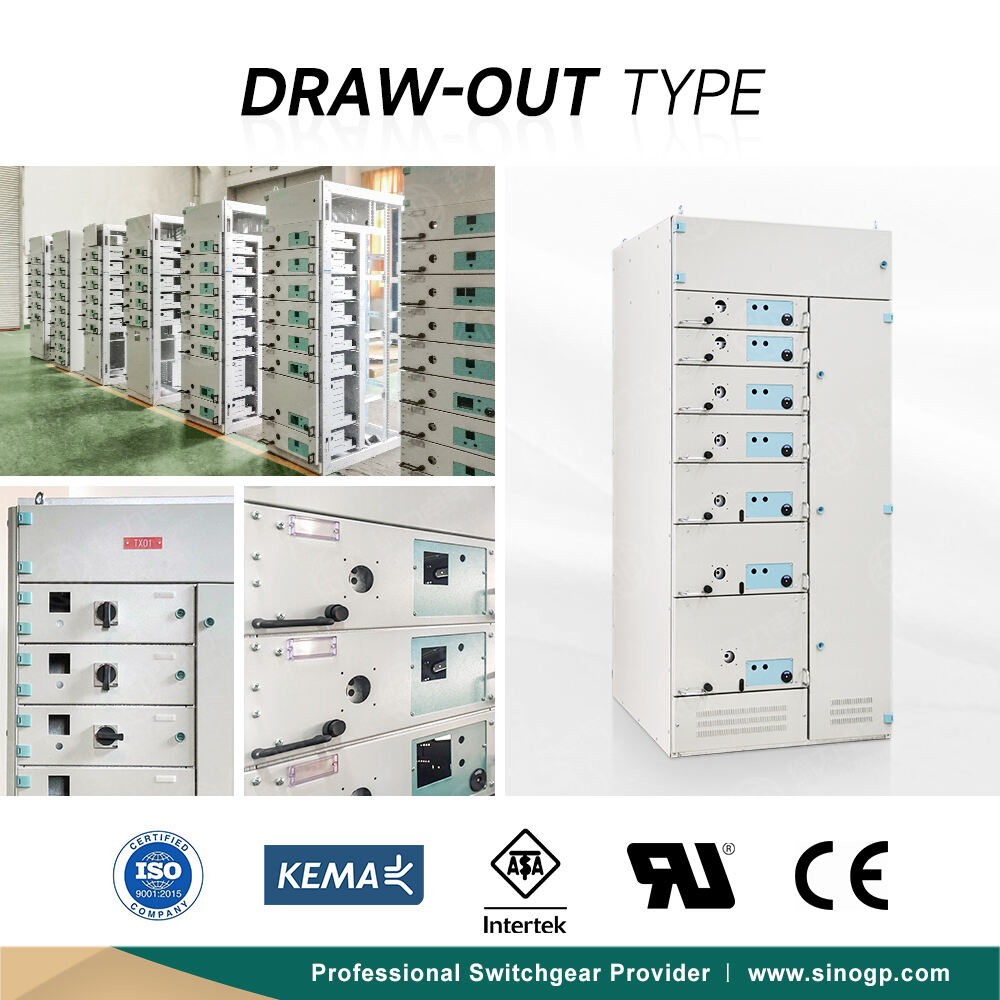

Change is constant in industry and so is the flexibility needed in MCC switchboards to adjust to changing motor systems. Each motor control module in the MCC switchboard is a standard withdrawable unit which means that when a module is faulty, the operators disconnect it and replace it with a spare, getting the motor operational again in 10-15 minutes. For non-modular systems, this time window can be 1-2 hours. This improves production continuity since downtime is significantly minimized. Furthermore, the modular design enables uncomplicated motor system expansion. For instance, if operators need to add more motors, they can do so without changing existing wiring or components of the MCC switchboard which promotes swift system adjustments. A case in point is in the plant example. Rather than developing a new control system to accommodate the MCC switchboard expansion, the MCC switchboard can handle the system expansion with 5 new control motor modules that can be added. Reliability is further enhanced with the modular design since drivers of motor systems fault is isolated.

GPSwitchgear’s MCC switchboard incorporates top-notch modular parts, with rigorous validation of compatibility, allowing flawless interchangeability and addition of new components, thus enhancing the flexible and dependable management of motors.

Hot News

Hot News2026-02-02

2026-01-23

2026-01-20

2026-01-18

2026-01-16

2026-01-15