The dielectric strength of a material, measured in kilovolts per millimeter (kV/mm), tells us how much electric field an insulator can handle before it breaks down completely. For circuits operating at low voltages below 1 kV, materials with high dielectric properties work best. Ceramics typically offer strengths between 12 and 20 kV/mm, while glass reinforced plastics fall around 10 to 15 kV/mm. These materials create a good buffer against electrical currents, even when there are sudden voltage spikes reaching about 150% of normal levels according to standards like IEC 60664-1. Humidity poses a real problem though. Moisture can cut the effectiveness of these insulators by anywhere from 15% to 30%, especially in materials with tiny pores. That's why engineers often specify surface sealed composites for reliable long term performance. When insulation fails due to insufficient resistance, dangerous tracking occurs. This creates carbon paths on the material surface that never go away, gradually destroying the protective qualities of the insulation over time.

The mechanical rigidity of components plays a vital role in preventing gradual wear caused by thermal stress and vibrations, which are major contributors to insulator failures. When materials experience thermal cycling with temperature changes exceeding 50 degrees Celsius, they expand and contract repeatedly, creating tiny cracks that slowly degrade their electrical properties. Rigid composite materials like mineral filled epoxies that have a coefficient of thermal expansion under 30 parts per million per degree Celsius tend to stay dimensionally stable and stop these cracks from spreading further. Vibration resistance matters just as much, especially for equipment tested according to standards such as IEC 60068-2-6. Industrial environments often deal with vibrations between 5 and 200 hertz, but rigid designs can handle accelerations up to 10 G forces without bending or warping, maintaining safe creepage distances and overall structural soundness. Components built this way typically last well beyond 100,000 operational cycles even in tough conditions found in motor control centers across manufacturing facilities.

| Property | Failure Risk Without Rigidity | Rigid Material Performance |

|---|---|---|

| Thermal Cycling (Δ80°C) | Microcrack formation (– 70% failure rate) | <0.1% dimensional change |

| Vibration (15 G-force) | Resonance fractures (– 50% lifespan) | 10x fatigue resistance |

| Combined Stress | Delamination & tracking | Maintains dielectric integrity |

The creepage distance refers to the shortest path across an insulator's surface where electricity might travel. This measurement matters a lot when trying to prevent surface tracking issues in places that get damp or dirty. When salt from coastal areas mixes with dust and chemicals, these substances create conductive films on surfaces. In really humid conditions, this can boost leakage currents quite significantly, sometimes upwards of 60%. That's why industry guidelines set certain minimum distances for creepage. For regular environments, we typically see recommendations around 20 to 25 mm per kilovolt. But if the area has heavy pollution problems, those numbers jump up to about 31 to 40 mm per kilovolt. Manufacturers often design components with ribbed or corrugated surfaces to lengthen this path and stop contaminants from creating bridges. Some materials such as silicone rubber have properties that actually push away moisture, which makes them particularly good choices for low voltage equipment used outdoors or in industrial settings where exposure to harsh elements is inevitable.

The terms clearance and creepage describe two different but related safety measures in electrical systems. Clearance refers to the minimum distance through air between conductive parts, while creepage is the shortest distance along the surface of an insulating material. These distances matter because clearance stops sparks from jumping across gaps when voltages spike, and creepage prevents current from traveling along contaminated surfaces like those covered in dust or moisture. Take a system operating at 600 volts for instance. If the clearance isn't enough, we get dangerous flashovers right away. Not having sufficient creepage leads to something worse over time though carbon tracks slowly build up until they create a conductive path. Most industry standards call for around 5 to 8 millimeters of clearance and about 15 millimeters of creepage for every kilovolt. Practical experience shows that getting both these measurements right cuts down short circuit incidents by roughly three quarters in humid settings. This dual protection approach really makes all the difference when it comes to keeping low voltage insulation reliable under real world conditions.

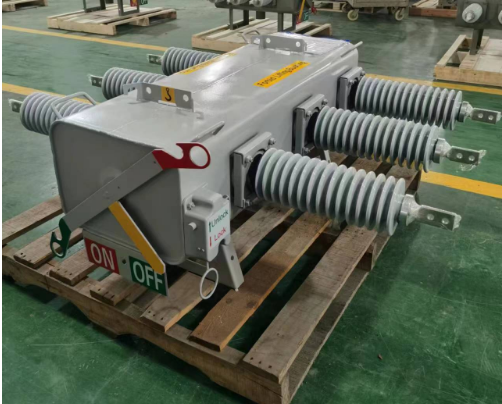

Low voltage insulators are engineered for precise operational environments to prevent electrical failures. Different insulator types address unique challenges across applications, ensuring reliable equipment protection through specialized designs.

Standoff insulators serve as physical barriers between live wires and grounded parts within switchgear and control panels. These long ceramic or polymer components create the necessary space gaps that stop dangerous arcs when voltages spike unexpectedly. Most standoff designs can handle temperatures reaching around 120 degrees Celsius without breaking down. They also stop unwanted current leaks and stay firm even when subjected to intense short circuit forces. This strength matters a lot because it keeps conductors in place despite vibrations or strong magnetic pulses that might otherwise push them out of position. The added stability means fewer chances of unintended contacts forming in those crowded control panel setups where space is at a premium.

The insulators used in solar combiner boxes need to handle some pretty specific challenges related to photovoltaic systems. Think about things like constant UV exposure, dramatic temperature changes from day to night, and all that moisture buildup when dew forms. That's why we see custom made busbar insulators with special hydrophobic silicone coatings. These coatings basically repel water and stop dust from sticking, which helps maintain good electrical resistance even after months outside. The design itself is interesting too - those ribs on the surface actually create about 40% more creepage distance than regular smooth designs. This extra space between conductive parts makes it much harder for partial discharges to start up, something that can lead to bigger problems down the road. When DC conductors get properly encapsulated, they avoid creating those pesky leakage paths caused by dew. Field studies show around 23% of combiner box failures come from exactly this kind of issue. And speaking of performance metrics, these specialized insulators keep their insulation resistance well above 1000 megaohms even through repeated heating and cooling cycles.

Understanding failure modes in low voltage insulators is essential for maintaining electrical system reliability. Common issues include:

When these mechanisms fail, they put all the equipment downstream at risk for things like short circuits, dangerous arcing, and even fires that endanger workers and disrupt operations completely. If insulators start to degrade and nobody notices, problems tend to spread throughout the whole system, leading to unexpected shutdowns and expensive fixes down the road. According to industry reports, around 35% or more of switchgear issues in factories come from problems with insulation. That's why picking the right insulators matters so much. Look for ones that match what kind of environment they'll be working in pollution levels, temperature extremes, how much vibration there is etc. Getting this right helps keep equipment running longer and maintains reliable power supply across different industrial settings.

Hot News

Hot News2026-02-02

2026-01-23

2026-01-20

2026-01-18

2026-01-16

2026-01-15